Laser Rust Paint Coated Removal Cutting Cleanging and Welding Machine

Basic Info.

| Model NO. | 1500w 2000w |

| Laser Machinery | Fiber Laser |

| Laser Source | 1000W/1500W/2000W |

| Laser Classification | Optical Fiber Laser |

| Fiber Welder | 2000W Laser Source |

| Type | Portable Handheld |

| Laser Welder | 1500W Laser Welding Machine |

| Laser Welding | 1000W Portable Laser Welding |

| Fiber Welding Machine | Laser |

| Working Voltage | AC220V or 380V |

| Laser Generator | 1000W/2000W/3000W |

| Cutting Thickness | 2mm-8mm |

| Fiber Laser Welder | Portable Welding Machine |

| Transport Package | Wood Case |

| Specification | 1000W OR 1500W |

| Trademark | ALLWIN |

| Origin | China |

| HS Code | 8515809010 |

| Production Capacity | 200/Month |

Packaging & Delivery

Package Size 70.00cm * 40.00cm * 120.00cm Package Gross Weight 260.000kgProduct Description

1500W 2000W Continous Laser Cleaning Machine Rust Removal rusty cleaning machine

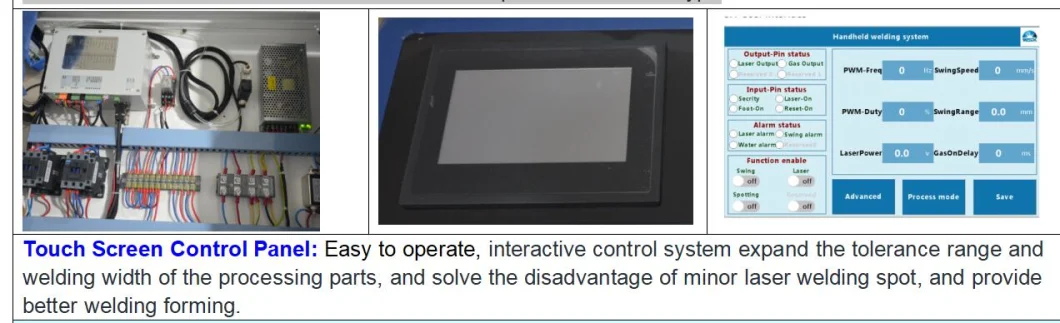

Laser cleaning is an effective method to remove dirt particles and films of different materials and sizes on solid surfaces.Laser cleaning is to form a laser beam with a specific spot shape and energy distribution after optical focusing and spot shaping of a continuous or pulsed laser with high brightness and good directionality.After the contaminant material absorbs the laser energy, it will produce a series of complex physical and chemical processes such as vibration, melting, burning, and even gasification, and finally make the contaminant detach from the surface of the material. Even if the laser acts on the cleaned surface, most All are reflected off, and will not cause damage to the substrate, so as to achieve the effect of cleaning.Handheld Fiber Laser Cleaning Machine Features1. Non-contact cleaning with laser beam will not damage the surface of the substrates.2. Precise cleaning to achieve precise location, precise size selective cleaning.3. No chemical cleaning fluid, no consumables, safe and environmentally friendly in cleaning process.4. It is easy to use, just power on, and it can be hand-held or cooperated with a manipulator to realize automatic cleaning.5. The cleaning efficiency is higher than traditional cleaning tools to save time and labor cost.6. The portable laser cleaning system is stable, almost no need of care and maintenance.7. It can be used as a part of production lines for surface treatment in modern manufacturing.8. With over 10 years of experience.

Laser welder has long life but does not need a lot of consumables;

| Machine Model | AW-1000W | AW-1500W | AW-2000W |

| Laser Power | 1000W | 1500W | 2000W |

| Laser Wavelength | 1064-1080nm | 1064-1080nm | 1064-1080nm |

| Welding Depth | 2mm | 4mm | 7mm |

| Modulation Frequency | 20-20kHz | 20-20kHz | 20-20kHz |

| Energy Stability | <3% | <3% | <3% |

| Blowing Protection | Argon/Nitrogen | Argon/Nitrogen | Argon/Nitrogen |

| Electricity Demand | AC 220V/50Hz | AC 220V/380V/50Hz | AC 220V/380V/50Hz |

| Machine Power | 5.6KW | 7.1KW | 9.1KW |

| Cooling System | Water | Water | Water |

| Dimension | 1130x590x1200mm | 1130x590x1200mm | 1130x590x1200mm |

| Weight | 230kg | 230kg | 230kg |

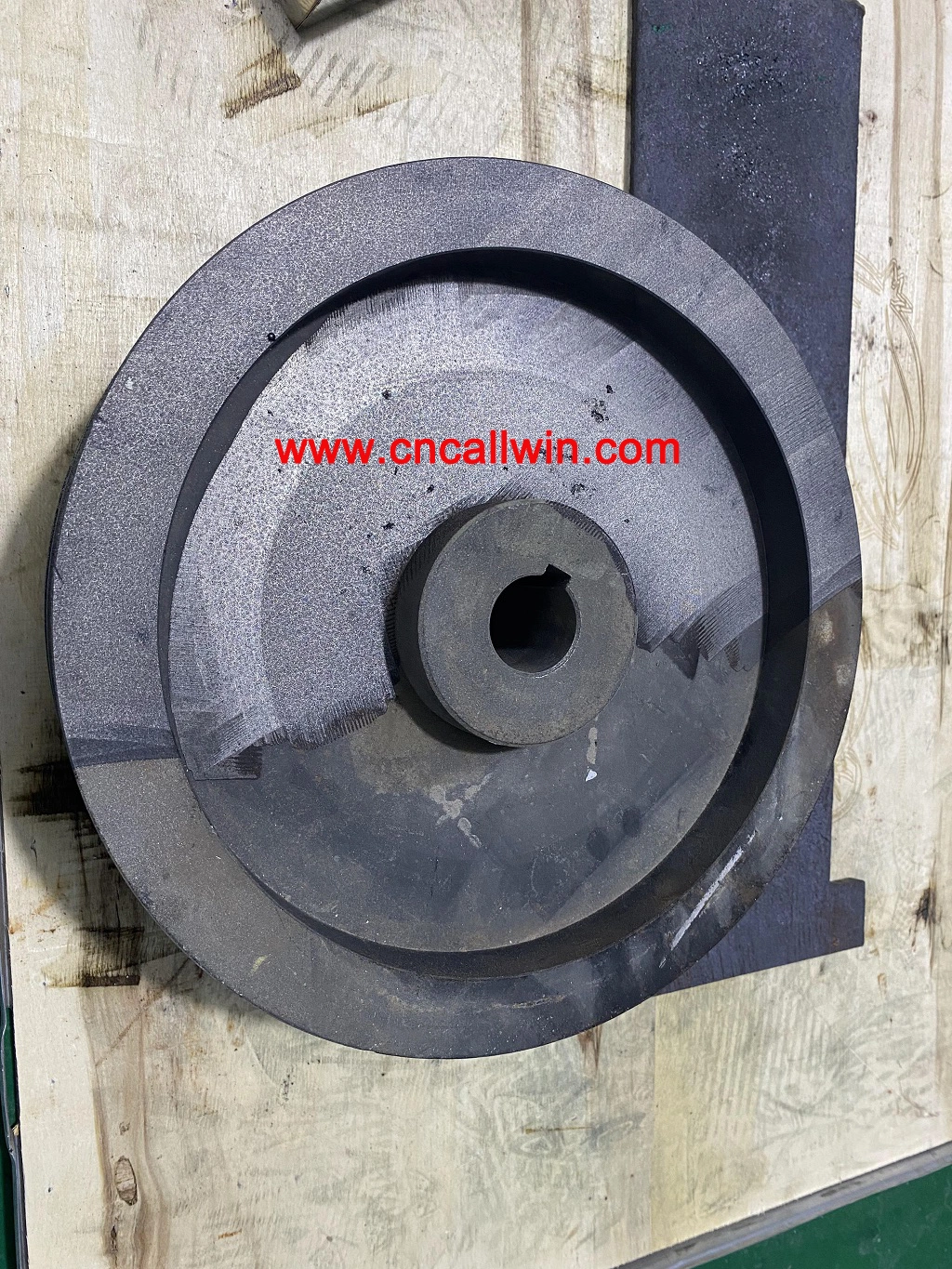

Projects for rust removal machine

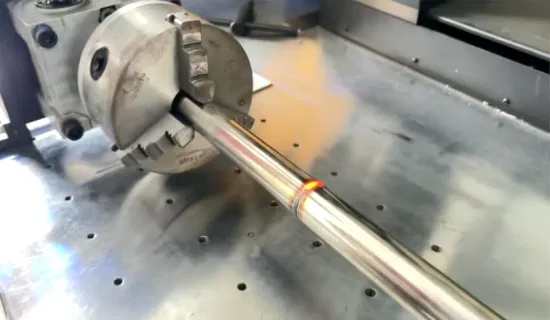

Projects for Fiber laser welding machine

laser cleaning /rust removing

Portable Handheld Fiber Laser Cleaner Advantages Compared with the traditional cleaning methods such as mechanical friction cleaning,chemical corrosion cleaning, liquid solid strong impact cleaning and high frequency ultrasonic cleaning, manual laser cleaner has obvious advantages.1. It is a "green" cleaning method. It does not need any chemical reagent and cleaning liquid. The waste cleaned is basically solid powder. It is small, easy to store and recycle, and can easily solve the environmental pollution caused by chemical cleaning.2. The traditional cleaning method is contact cleaning, which has mechanical force on the surface of the cleaning object, damages the surface of the object or the cleaning medium adheres to the surface of the object being cleaned, which can not be removed, resulting in secondary pollution. The non-abrasion and non-contact nature of laser cleaning make these problems easy to solve.3. Laser can be transmitted through optical fibers, cooperate with robots, realize remote operation conveniently, and can clean the parts that are not easy to reach by traditional methods, which can ensure the safety of personnel in some dangerous places.4. The portable fiber laser cleaner can remove pollutants and contaminants from many types of materials without damaging.5. The portable fiber laser cleaner has high efficiency and saves time.6. Although the purchase of laser cleaning system has a high one-time investment in the early stage, the cleaning system can be used stably for a long time with low operation cost. Laser cleaning is considered to be the most reliable and effective solution because of its non-abrasive, non-contact, non-thermal effect and applicability to various materials.

For more details and how to maintance fiber laser welding machine

please input "ALLWIN CNC MACHINERY"IN GOOGLE.